Thermal Oil Heater

MODEL:TOH

POWER RATED:400V 3PH,50Hz

MEDIUM:Heat Transfer Oil

TEMP CONTROL RANGE:RT~350℃

TEMP CONTROL ACCURACY:±1℃

HEATING:ELECTRIC HEATING

TEMP CONTROL:SSR/SCR Thyristor

INTERACTION:PID Temp Controller/PLC+HMI

COLOR:Customizable

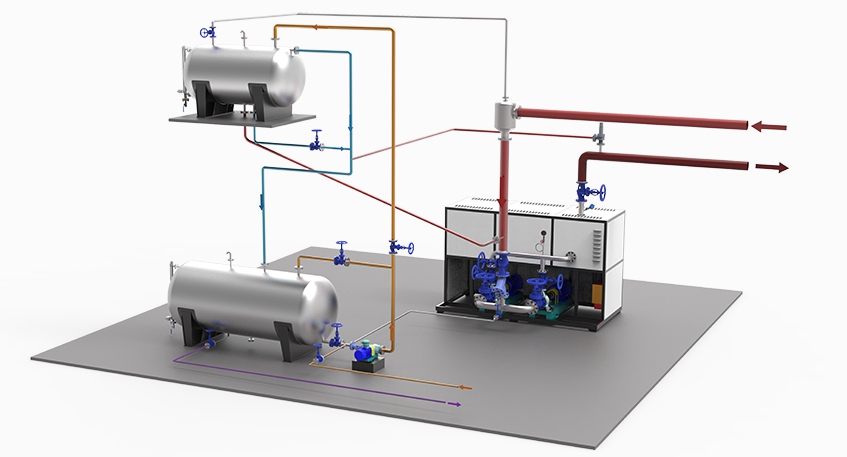

Our thermal oil heater is a industrial heating device designed to provide high-temperature heat with low operating pressure. Unlike traditional steam boilers, this system utilizes thermal oil as a heat transfer medium, circulating it through a closed-loop system to deliver precise, uniform, and efficient heat to various industrial processes.

By leveraging electrical energy as a clean power source, this heater offers an environmentally friendly alternative to fossil fuel-based systems, ensuring zero emissions and high thermal efficiency.

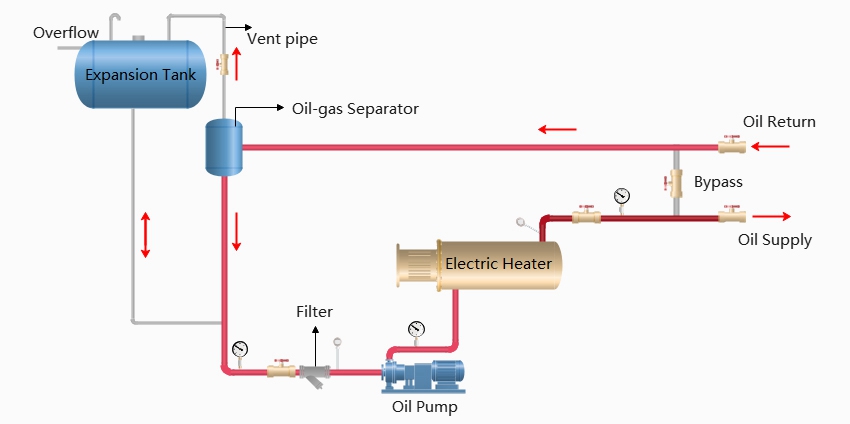

How It Works

The system operates on a simple yet highly effective principle:

- Heating: The immersion electric heating elements are directly inserted into the thermal fluid (heat transfer oil) within the manifold.

- Circulation: A high-temperature circulating pump forces the oil to flow in a liquid phase.

- Heat Exchange: The heated oil travels through the pipeline to the heating consumer (e.g., reactors, drying equipment, heat exchangers) and returns to the heater to be reheated.

- Control: An advanced PID temperature control system maintains the exact temperature required, typically up to 350°C (662°F) , with extreme precision.

Key Features & Advantages

- High Temperature, Low Pressure: Achieves operating temperatures of up to 350°C while maintaining very low system pressure, making it safer than steam systems.

- Energy Efficiency: Closed-loop circuit minimizes heat loss. Electric heating offers nearly 100% energy conversion efficiency at the point of use.

- Precise Temperature Control: Advanced digital PID controllers maintain temperature stability within a narrow range (±1°C), ensuring product quality and process consistency.

- Environmentally Friendly: Zero emissions on-site; no combustion, flue gas, or soot. It is a clean energy solution.

- Safe & Reliable: Equipped with multiple safety protection devices, including over-temperature alarms, low oil level alarms, flow failure protection, and pressure relief systems.

- Easy Installation & Operation: Compact skid-mounted design allows for quick installation. Simple plug-and-play operation with user-friendly HMI (Human-Machine Interface).

- Long Service Life: High-quality electrical heating elements and thermal oil ensure long-term stable operation with minimal maintenance.

Applications

Electric Thermal Oil Heaters are widely used across various industries where high-temperature heating is required:

- Chemical Industry: Heating reactors, autoclaves, and distillation units.

- Oil & Gas: Preheating heavy oil, bitumen heating, and pipeline tracing.

- Construction Materials: Heating presses for plywood, particleboard, and laminates.

- Food Industry: Frying, oil heating, and distillation processes.

- Textile Industry: Drying and setting machines (Stenter machines).

- Rubber & Plastics: Heating calenders, mixers, and extruders.

- Renewable Energy: Biomass pyrolysis and biodiesel production.

CONTROL

- Digital PID temperature controller

- SSR or SCR power controllers

- Brand electrical components (Siemens, Omron, Schneider Electric, ABB, etc.)

- Heat ON/OFF switch

- Audible and visible alarm indicators

- Control Accuracy: ±1°C

- 3∼3000KW input power supply to your specifications

- Temperature recorder (optional)

- PLC with HMI(touch panel) (optional)

- RS485 communication protocols (optional)

- Programmable temperature controllers (optional)

► SAFETY PROTECTION

- Over Temperature Alarm, Automatic Interlock Protection

- Pressure Detection: pressure gauge with electric contact which show real pressure of entire system was equipped on the piping. Control system will alarm immediately when pressure below a certain value, meanwhile the Heater stop too.

- Oil Low Level Detection: Expansion tank is equipment with a ball float level controller, Control system will alarm immediately when pressure below a certain value, meanwhile the Heater stop too.

SPECIFICATIONS

| Model | Heating Capacity | Pump Capacity | Pump Flow | Pump Head | Inlet/Outlet Size | Overall Dimensions |

|---|---|---|---|---|---|---|

| TOH3-0.75 | 3KW | 0.75KW | 1.5m³/h | 22m | DN20/DN20 | L1800×W600×H1400 mm |

| TOH6-0.75 | 6KW | 0.75KW | 1.5m³/h | 22m | DN20/DN20 | L1800×W600×H1400 mm |

| TOH12-1.5 | 12KW | 1.5KW | 6m³/h | 28m | DN25/DN25 | L2000×W600×H1400 mm |

| TOH24-2.2 | 24KW | 2.2KW | 10m³/h | 28m | DN32/DN32 | L2000×W600×H1400 mm |

| TOH36-3 | 36KW | 3KW | 12.5m³/h | 30m | DN50/DN50 | L2000×W650×H1450 mm |

| TOH48-4 | 48KW | 4KW | 16m³/h | 32m | DN50/DN50 | L2100×W650×H1450 mm |

| TOH60-5.5 | 60KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W650×H1450 mm |

| TOH72-5.5 | 72KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W750×H1750 mm |

| TOH90-5.5 | 90KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W750×H1750 mm |

| TOH120-7.5 | 120KW | 7.5KW | 30m³/h | 48m | DN65/DN65 | L2300×W750×H1750 mm |

| TOH150-7.5 | 150KW | 7.5KW | 30m³/h | 48m | DN65/DN65 | L2400×W750×H1750 mm |

| TOH200-11 | 200KW | 11KW | 45m³/h | 40m | DN80/DN80 | L2400×W1000×H1950 mm |

| TOH250-11 | 250KW | 11KW | 45m³/h | 40m | DN80/DN80 | L2400×W1000×H1950 mm |

| … | … | … | … | … | … | … |

Notes: For more models, please contact us. The unit could be entirely bespoke, we can design and tailor heating capacity, pump, etc. to your specification.

SCHEMATIC DIAGRAM