Glycol Circulation Heater

MODEL:TGH

POWER RATED:400V 3PH,50Hz

MEDIUM:Water

TEMP CONTROL RANGE:RT~180℃

TEMP CONTROL ACCURACY:±1℃

HEATING:ELECTRIC HEATING

TEMP CONTROL:SSR/SCR Thyristor

INTERACTION:PID Temp Controller/PLC+HMI

Color:Customizable

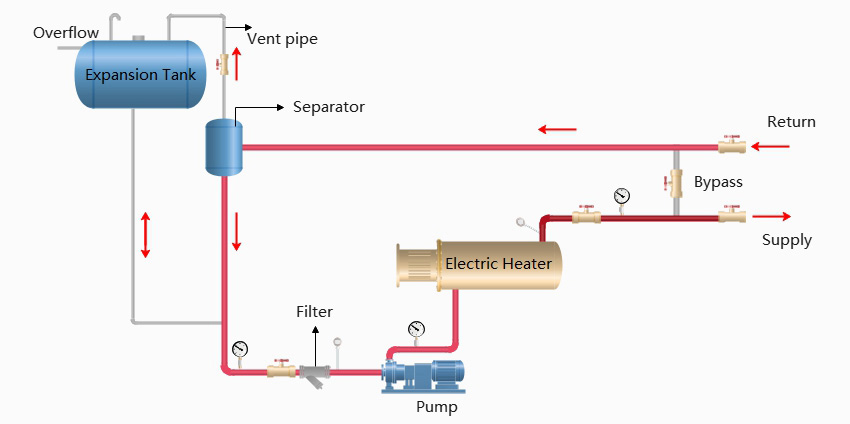

Our glycol circulation heater is a compact, self-contained unit designed to provide reliable and energy-efficient hot water for residential, commercial, and industrial heating systems. By combining a high-performance electric heating element with an integrated circulation pump, it ensures rapid and uniform heat distribution through radiators, underfloor heating loops, fan coil units, or heat exchangers. Ideal for closed-loop hydronic systems, this unit delivers precise temperature control with minimal maintenance and zero emissions.

APPLICATIONS

- Reactor, Distillation still, etc.

- Evaporator

- Heat Press

- Roller

- Mold

- Exchanger

- Oven

- Dryer

- Tank (Asphalt tank, Grease tank, etc.)

FEATURES

- All welded construction

- Thermal insulation provided to prevent heat loss

- Low pressure and high temperature

- Isolation gate valves and strainer

- Terminal enclosures available for easy wiring

- Functional test of system prior to shipment

- Highly customizable to meet specifications

CONTROL

- Digital PID temperature controller

- SSR or SCR power controllers

- Brand electrical components (Siemens, Omron, Schneider Electric, ABB, etc.)

- Heat ON/OFF switch

- Audible and visible alarm indicators

- Control Accuracy: ±1°C

- 3∼3000KW input power supply to your specifications

- Temperature recorder (optional)

- PLC with HMI(touch panel) (optional)

- RS485 communication protocols (optional)

- Programmable temperature controllers (optional)

SAFETY PROTECTION

- Over Temperature Alarm, Automatic Interlock Protection

- Pressure Detection: pressure gauge with electric contact which show real pressure of entire system was equipped on the piping. Control system will alarm immediately when pressure below a certain value, meanwhile the Heater stop too.

SPECIFICATIONS

| Model | Heating Capacity | Pump Capacity | Pump Flow | Pump Head | Inlet/Outlet Size | Overall Dimensions |

|---|---|---|---|---|---|---|

| TGH3-0.75 | 3KW | 0.75KW | 1.5m³/h | 22m | DN20/DN20 | L1800×W600×H1400 mm |

| TGH6-0.75 | 6KW | 0.75KW | 1.5m³/h | 22m | DN20/DN20 | L1800×W600×H1400 mm |

| TGH12-1.5 | 12KW | 1.5KW | 6m³/h | 28m | DN25/DN25 | L2000×W600×H1400 mm |

| TGH24-2.2 | 24KW | 2.2KW | 10m³/h | 28m | DN32/DN32 | L2000×W600×H1400 mm |

| TGH36-3 | 36KW | 3KW | 12.5m³/h | 30m | DN50/DN50 | L2000×W650×H1450 mm |

| TGH48-4 | 48KW | 4KW | 16m³/h | 32m | DN50/DN50 | L2100×W650×H1450 mm |

| TGH60-5.5 | 60KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W650×H1450 mm |

| TGH72-5.5 | 72KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W750×H1750 mm |

| TGH90-5.5 | 90KW | 5.5KW | 18m³/h | 40m | DN50/DN50 | L2300×W750×H1750 mm |

| TGH120-7.5 | 120KW | 7.5KW | 30m³/h | 48m | DN65/DN65 | L2300×W750×H1750 mm |

| TGH150-7.5 | 150KW | 7.5KW | 30m³/h | 48m | DN65/DN65 | L2400×W750×H1750 mm |

| TGH200-11 | 200KW | 11KW | 45m³/h | 40m | DN80/DN80 | L2400×W1000×H1950 mm |

| TGH250-11 | 250KW | 11KW | 45m³/h | 40m | DN80/DN80 | L2400×W1000×H1950 mm |

| … | … | … | … | … | … | … |

Notes: For more models, please contact us. The unit could be entirely bespoke, we can design and tailor heating capacity, pump, etc. to your specification.