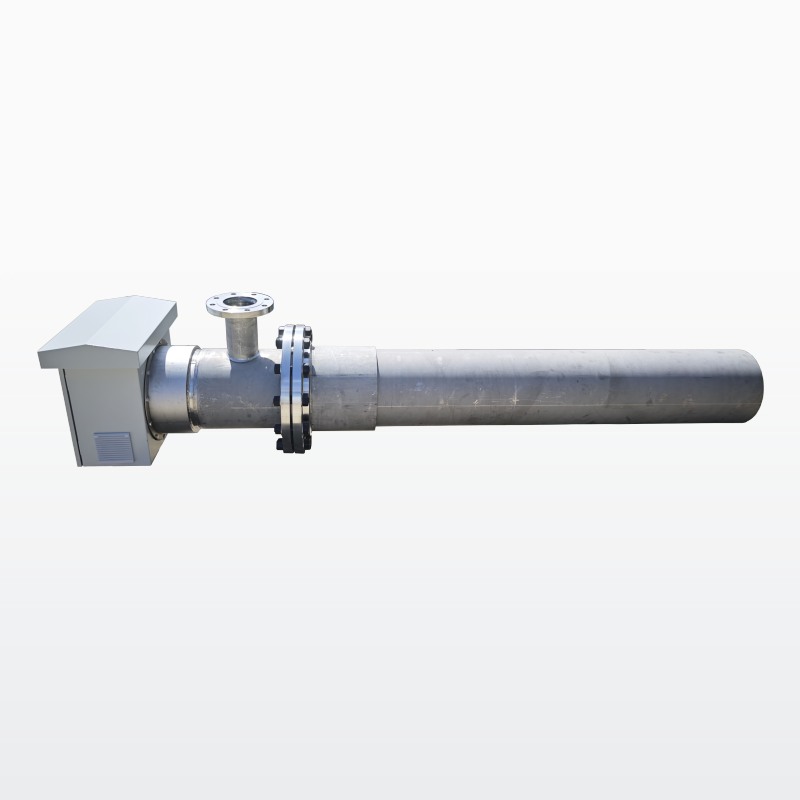

Tank Suction Heater

MODEL:ERH

POWER RATED:400V 3PH,50Hz

MEDIUM:Fluid & Gas

TEMP CONTROL RANGE:RT~800℃

TEMP CONTROL ACCURACY:±1℃

HEATING:ELECTRIC HEATING

TEMP CONTROL:SSR/SCR Thyristor

INTERACTION:PID Temp Controller/PLC+HMI

COLOR:Customizable

Our Tank Suction Heaters are engineered to heat viscous fluids precisely at the point of withdrawal. Installed directly at the tank outlet, they ensure that liquids such as heavy crude, bitumen, polymers, and fuel oils reach the ideal pumping temperature—minimizing viscosity, reducing energy costs, and preventing flow interruptions. By heating only the fluid being drawn, these units offer rapid response and exceptional efficiency.

How It Works

The heater mounts through a tank nozzle or flange, with its elements immersed in the fluid near the suction pipe. As the pump draws fluid from the tank, the liquid passes over the heated surface, quickly raising its temperature just before entering the suction line. This localized, on‑demand heating avoids unnecessary heating of the entire tank volume, saving energy and time.

APPLICATIONS

- Oil & Gas – Crude oil, heavy fuel oil, and lube oil storage

- Asphalt & Bitumen – Terminals and road construction material heating

- Chemical Processing – Polymers, resins, sulfur, and high‑viscosity intermediates

- Food & Beverage – Vegetable oils, fats, chocolate, and molasses

- Marine & Offshore – Fuel tanks on vessels and drilling platforms

- Renewable Energy – Biodiesel and biofuel feedstocks

FEATURES

- Direct Immersion Design – Maximizes heat transfer by concentrating energy on the fluid being withdrawn.

- Customizable Watt Density – Tailored to prevent coking, fouling, or thermal degradation of sensitive fluids.

- Rugged Construction – Sheath materials available in carbon steel, stainless steel (304/316), Incoloy®, and exotic alloys for corrosion resistance.

- Integrated Temperature Control – Built‑in thermostats, RTD sensors, or PID controllers for precise temperature management.

- Simplified Installation – Flanged or threaded connections allow easy retrofitting to existing tanks.

- Low Maintenance – Robust heating elements and straightforward design reduce downtime and service costs.

TECHNICAL SPECIFICATION

- Surface load up to 10W/cm²

- Max working temperature up to 300℃

- Power supply customized upon request

- ∆ or Y electrical connections upon request

BENEFITS

- Easy to install

- Easy to control

- Easy to maintain

HEATING ELEMENTS